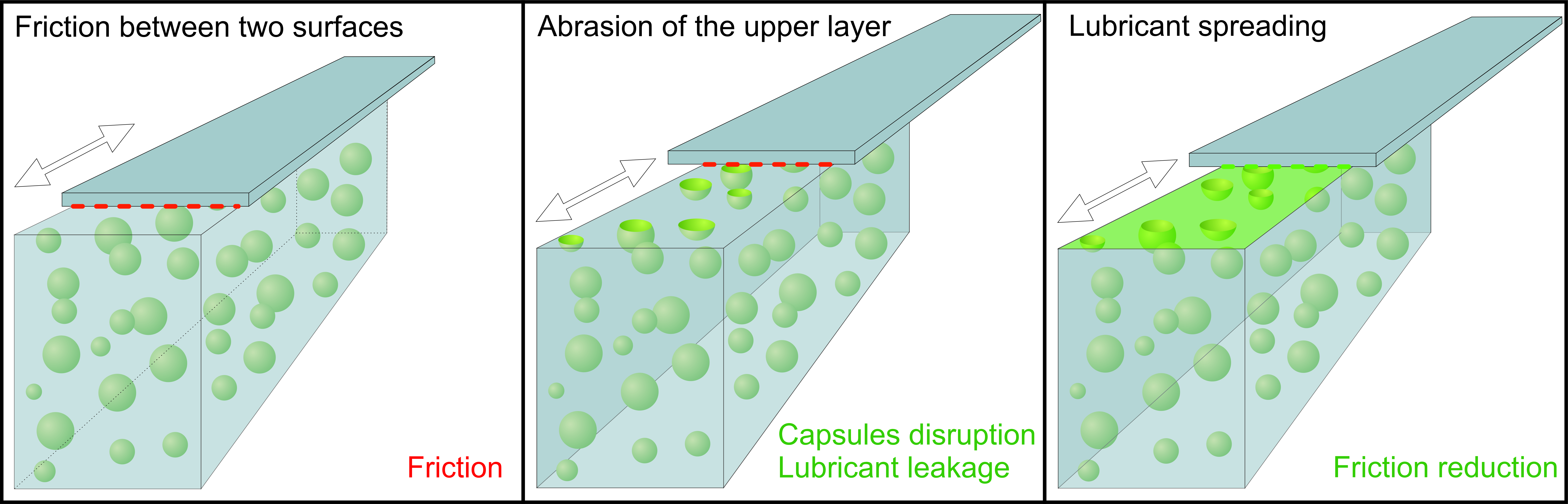

The goal of the project was to produce 3D-printed functional parts by integration of smart additives. One example of smart additive are core-shell microcpasules with liquid core made of a lubricating oil. The microcapsules containig up to 90wt.% of liquid lubricant and posessing an outstanding thermal stability (ca. 280°C) can be isolated as a dry powder and handled as a conventional solid additive. The capsules were integrated first into the filaments and further into the 3D-printed parts. Integration of other additives (UV stabilizers, energy storage materials like PCMs, healing components etc.) is also potentially possible.

Publications:

https://www.bibliothek.tu-chemnitz.de/ojs/index.php/innoTRAC/article/view/514

Website:

https://www.iap.fraunhofer.de/de/Pressemitteilungen/2021/mikroverkapselte-additive-neuartige-filamente-fuer-den-3D-Druck.html

https://www.iap.fraunhofer.de/de/Pressemitteilungen/2020/selbstschmierende-verbundwerkstoffe-skz-iap.html

Contact:

Fraunhofer IAP, Dr. Alexandra Latnikova, alexandra.latnikova@iap.fraunhofer.de, 0331 568-1207