Graded or multi-material parts made out of ceramic and/or metal exhibit inhomogeneous shrinkage during final sintering.

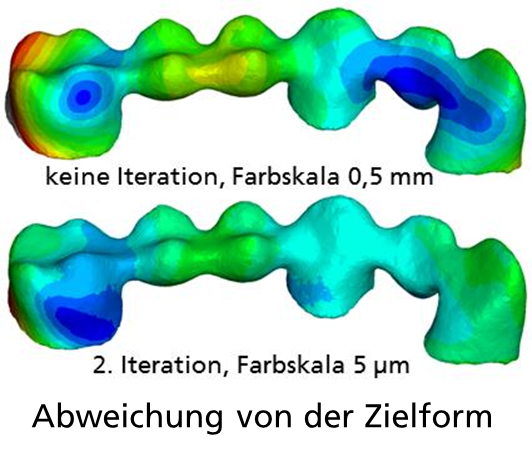

Depending on material and part geometry this results in an unwanted distortion and leads to deviations from the desired final part shape.

By using detailed sinter models the necessary geometric adjustments can be predicted in advance and thus compensated in the AM building process.

The printed green part will then shrink exactly to the desired target shape.

By numerical simulation extensive experimental test series to determine the optimal printing geometry and process parameters will be avoided.

In the calculations self-developed material routines are used in combination with commercial finite element programs.

Contact:

Fraunhofer IWM, Dr. Torsten Kraft, torsten.kraft@iwm.fraunhofer.de, +49 761 5142 248