Integration of additional electronic functions in components

The demands on microsystems technology and so-called heterointegration are constantly increasing to meet the needs of the population. Such functional microelectronic systems can, for example, be completely adapted to the patient's needs as prostheses or fill existing installation space with micrometer precision. The individual production of such complex units is no longer a utopia thanks to the combination of stereolithography and multi-jet modeling with microsystem technologies. Keyboards, displays, microcontrollers and the sensor-actuator periphery can be combined to individualized embedded systems using embedding techniques.

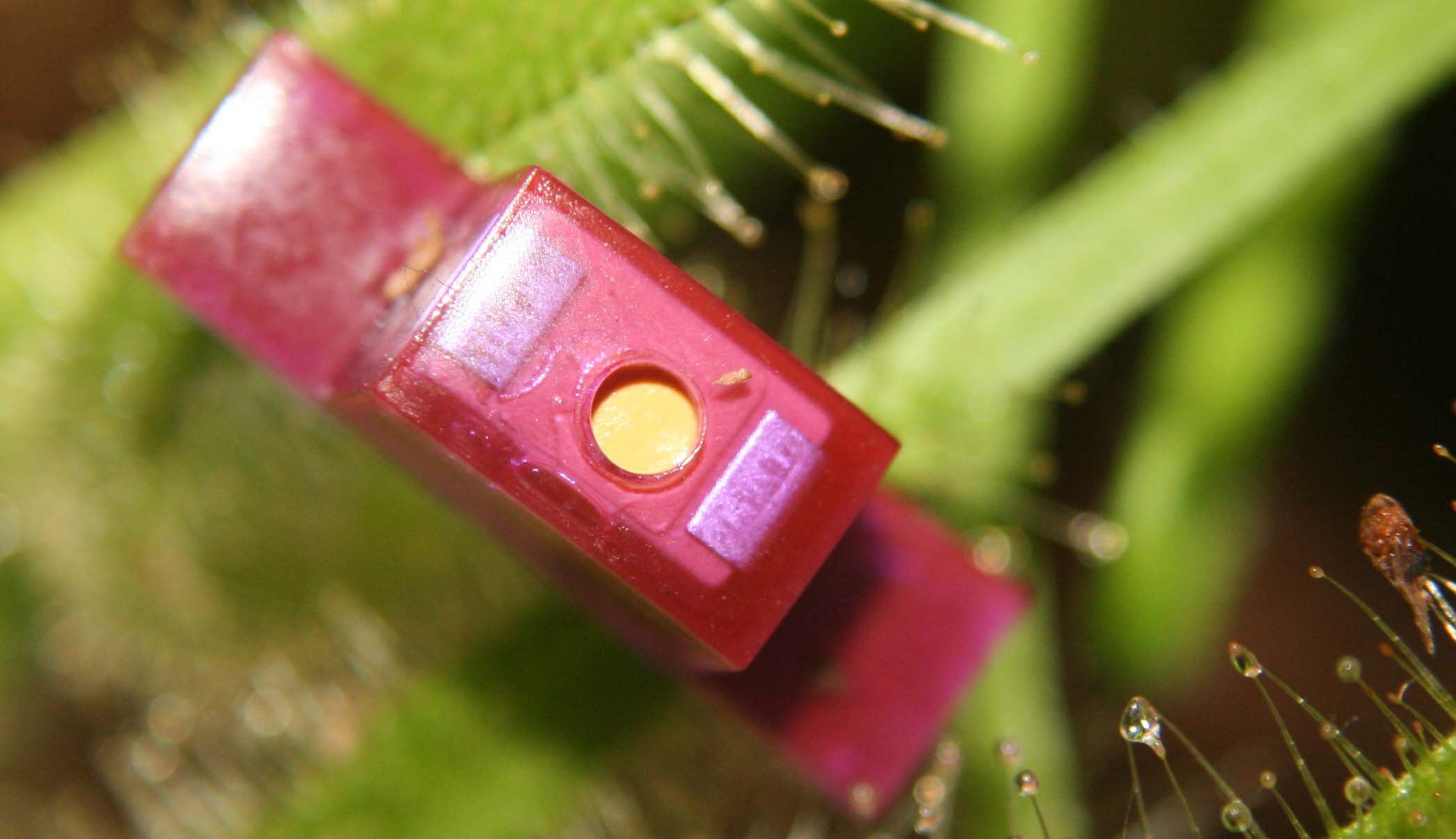

Integration of RFID chips

Thanks to rapid manufacturing, radio chips can even be integrated into metallic components. Researchers at the Fraunhofer Institute developed the process for Manufacturing Technology and Applied Materials Research IFAM in Bremen. The "intelligent" metal components are fitted with RFID chips in just one work step. The three-dimensional CAD model from the computer is built up layer by layer by a machine as a prototype. The Fraunhofer scientists can control this process so that the built-in RFID chip is completely enclosed by the material.