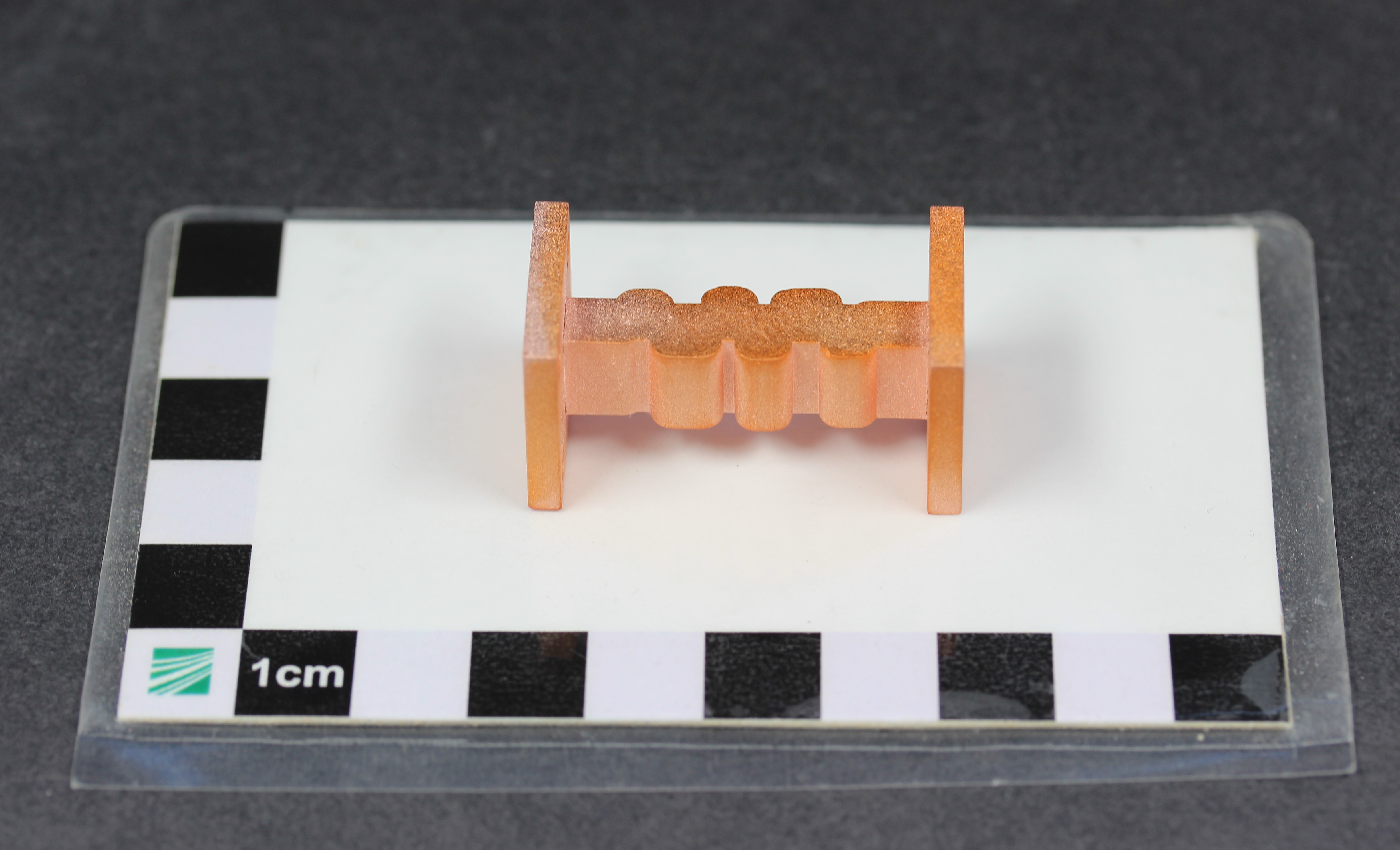

Antennas for satellite-to-earth communication require bulky filter components in the form of waveguides. Furthermore, the requirements for precision and surface quality increase with increasing frequency. The project is investigating the additive manufacturing of these components. Lithography-based metal manufacturing (LMM) can be used to produce components from metal with high dimensional resolution (100 µm in the sintered state) and high surface quality. This is realized by a metal powder filled paste, which additionally contains light-curing polymers: The paste is applied layer by layer and then selectively polymerized by UV light.

In the project, a collaboration between Fraunhofer IFAM Dresden and CNR-IEIIT (Institute of Electronics, Computer and Telecommunications Engineering, research institution of the National Research Council of Italy (CNR)) is formed. Pure copper filter components are developed, manufactured by additive manufacturing, and are subsequently characterized. The focus of Fraunhofer IFAM Dresden is on process development and suspension development for LMM as well as heat treatment (debinding and sintering) of the components and their geometrical measurement.

Link:

https://www.ifam.fraunhofer.de/en/Aboutus/Locations/Dresden/additive_manufacturing/LMM.html

Contact:

Fraunhofer IFAM, Dipl.-Ing. Jakob Scheibler, jakob.scheibler@ifam-dd.fraunhofer.de, +49 351 2537-420