Make additive methods calculable, control additive methods

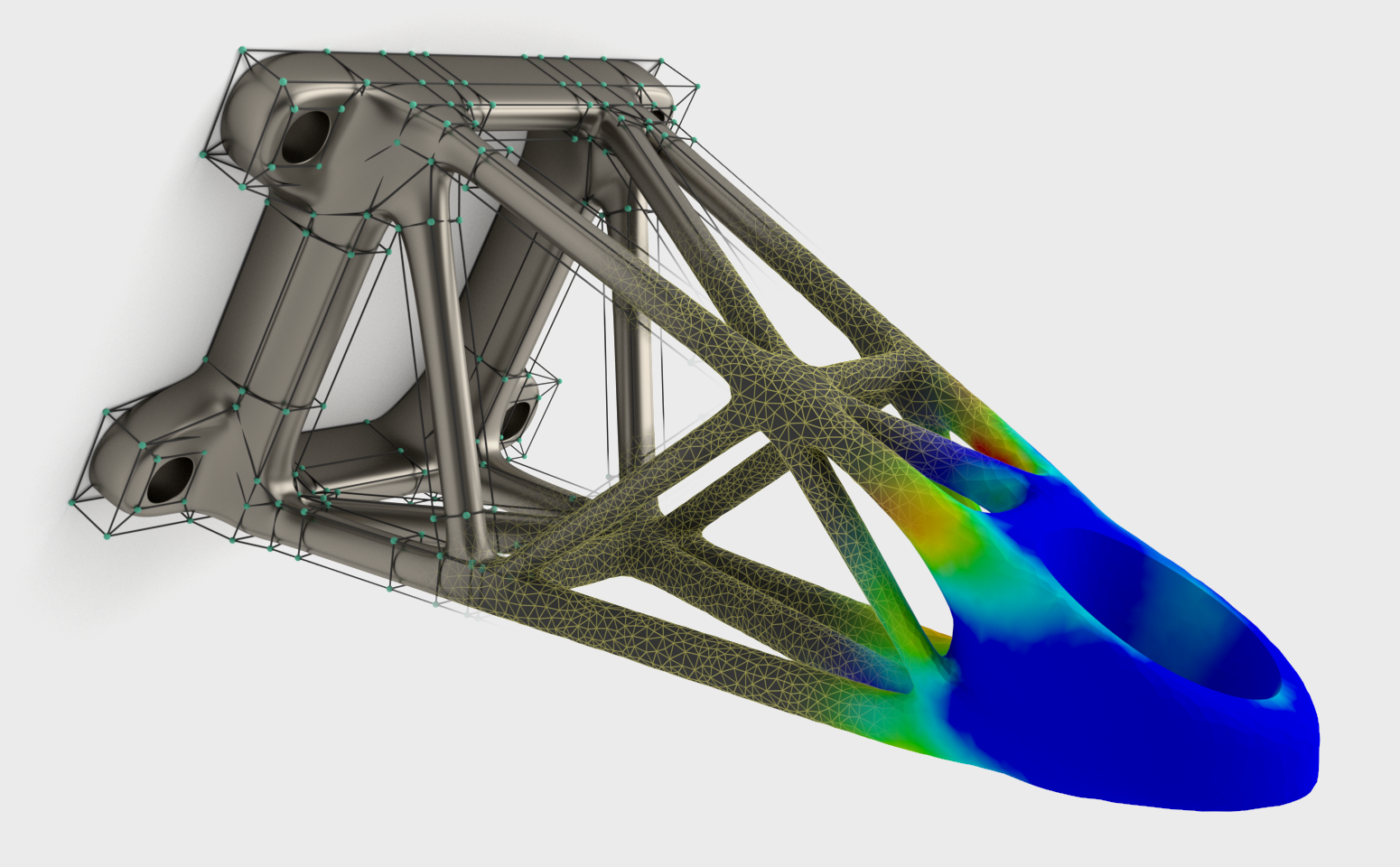

Additive manufacturing is closely linked to the digital control of the manufacturing process: Components are manufactured directly on the basis of a digital representation. The Fraunhofer Competence Field Additive Manufacturing develops algorithms to control additive manufacturing processes, for example to specifically design the optical properties of components, or to simulate individual process steps, e.g. to derive measures to reduce residual stresses and distortion.