- The result of the laser powder bed fusion process depends on more than 100 influencing factors, e.g. geometry and machine properties.

- Some influences can be predicted and accounted for before starting the manufacturing process. However, especially multidimensional interactions can deviate from the expected conditions.

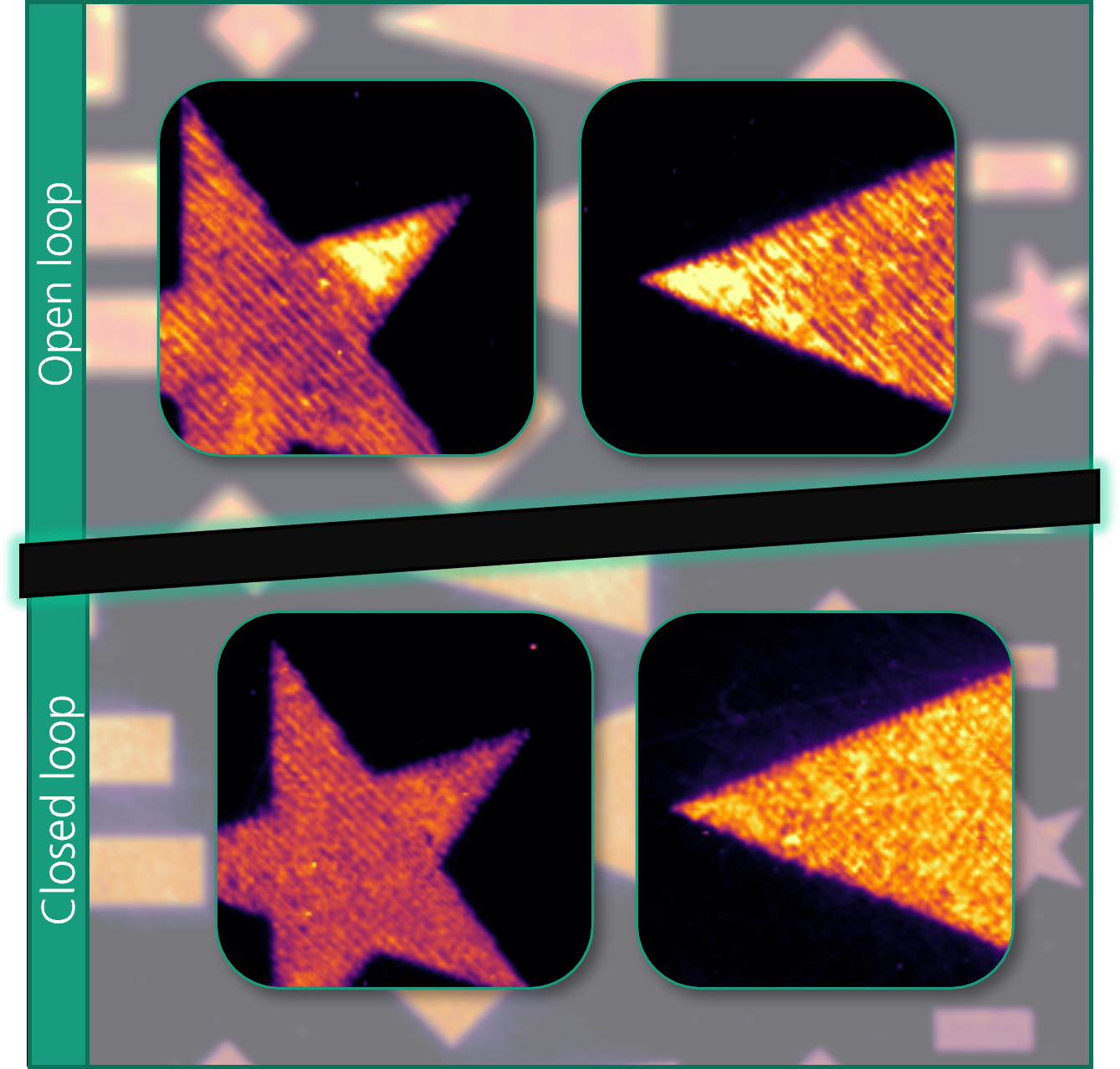

- As a potential solution, thermal emissions can be monitored and used to adapt the laser power in a closed loop control.

- At Fraunhofer Institute for Laser Technology (ILT), one approach for control on a vector-scale and one for the intermittent control of the following layer are investigated.

Contact:

Fraunhofer ILT, Niklas Prätzsch, M. Sc., Group Manager Process & Systems Engineering