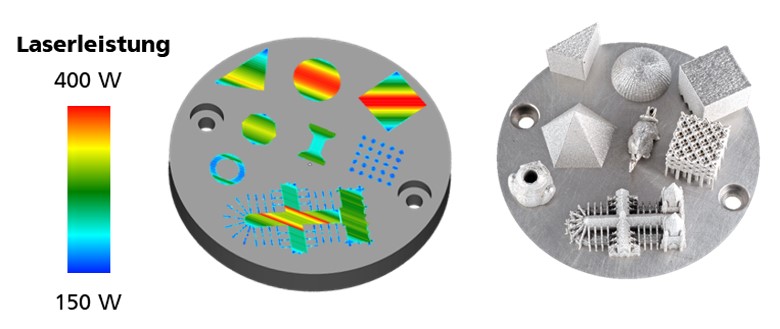

LPBF specimen with dynamically adapted Laser Power

- The process control of Laser Powder Bed Fusion (LPBF) is currently done without consideration of the part geometry and the application requirements by using constant process parameters for the entire part.

- By adapting the LPBF process control to the part geometry, there is a great potential to increase process speed, robustness and part quality.

- In addition, tailored component requirements can achieved by using different process parameters in different areas of the component depending on the desired function.

- The Fraunhofer ILT is developing this customized process control to increase the efficiency of LPBF manufacturing.

Publication:

Examination of the LPBF process by means of thermal imaging for the development of a geometric-specific process control, Author(s): Pichler, T.; Schleifenbaum, J.H. Bourell, D.L. ; Univ. of Texas, Austin: 30th Annual International Solid Freeform Fabrication Symposium - an Additive Manufacturing Conference 2019. Proceedings. Vol.2 : August 12-14, 2019, the University of Texas at Austin, Austin, Texas, USA; Austin, Tex.: University of Texas, 2019; pp.1511-1522

Contact:

Fraunhofer ILT, Tobias Pichler, tobias.pichler@ilt.fraunhofer.de, 0241/8906-8360