In the research project, the EUROfusion consortium is supplied by the additive manufacturing of tungsten in the development of plasma-facing components (PFC) for energy generation by means of nuclear fusion.

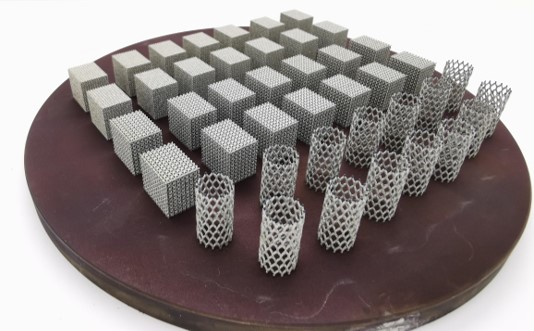

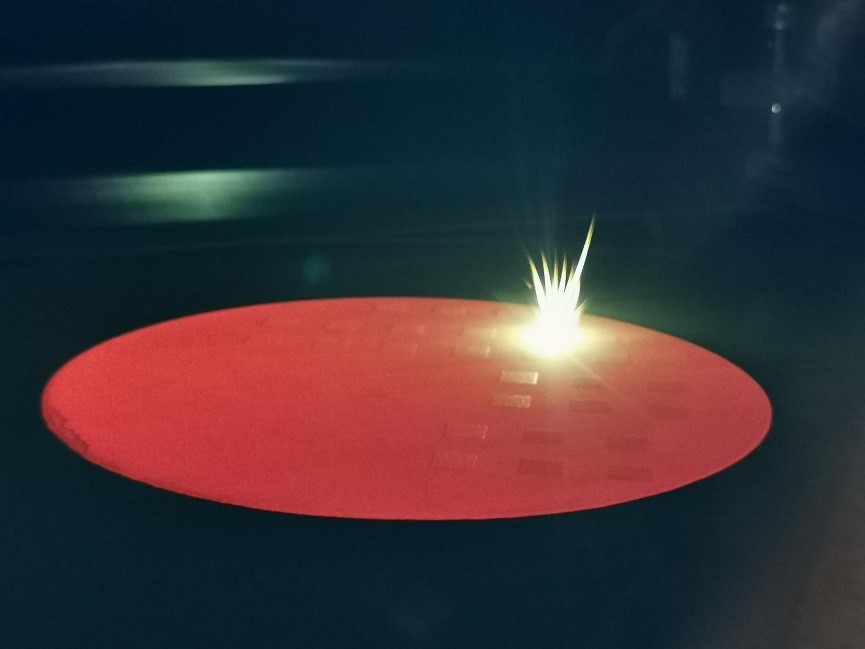

Laser powder bed fusion (PBF-LB/M) at Fraunhofer IGCV focuses on the dense and crack-free processing of filigree, numerically optimized lattice structures by using an inductive heating system that allows preheating of the build platform up to 800 °C. These high preheating temperatures of the substrate can reduce the susceptibility of the brittle material to cracking during material consolidation.