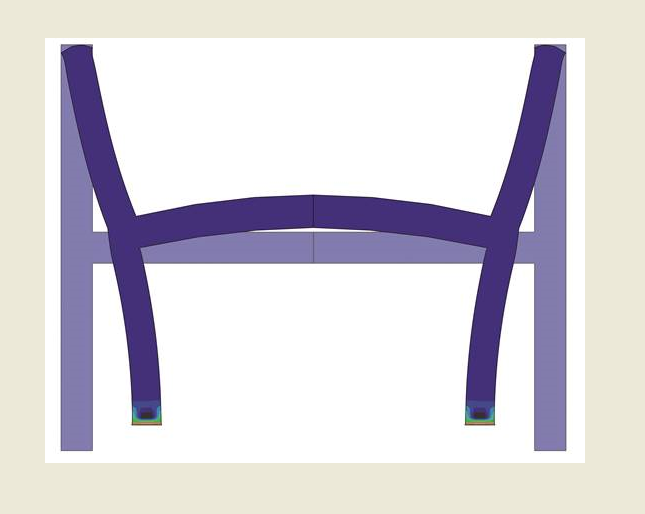

Resins for stereolithography shrink during polymerization. During the layer wise curing this leads to residual stresses and warpage.

The amount of residual stress depends on a complex interplay of shrinking, increasing stiffness, decreasing flowability and the shape of the component during polymerization.

The mechanical properties of curing resins can be analyzed at the Fraunhofer IWM experimentally. The results can be conveyed into a material model that help to predict the residual stresses and the warpage.

As the model takes the kinetics into account different types of resins as well as different process parameters can be assessed and optimized.

Projects:

SimGen (FhG)

Publication:

C. Koplin, M. Gurr, R. Kübler, R. Mülhaupt, R. Jaeger, Formgenauigkeit in der Stereolithographie, Konstruktion, (2009), 11/12, p. IW11-IW12

Contact:

Fraunhofer IWM, Dr. Raimund Jaeger, raimund.jaeger@iwm.fraunhofer.de, +49 761 5142 284