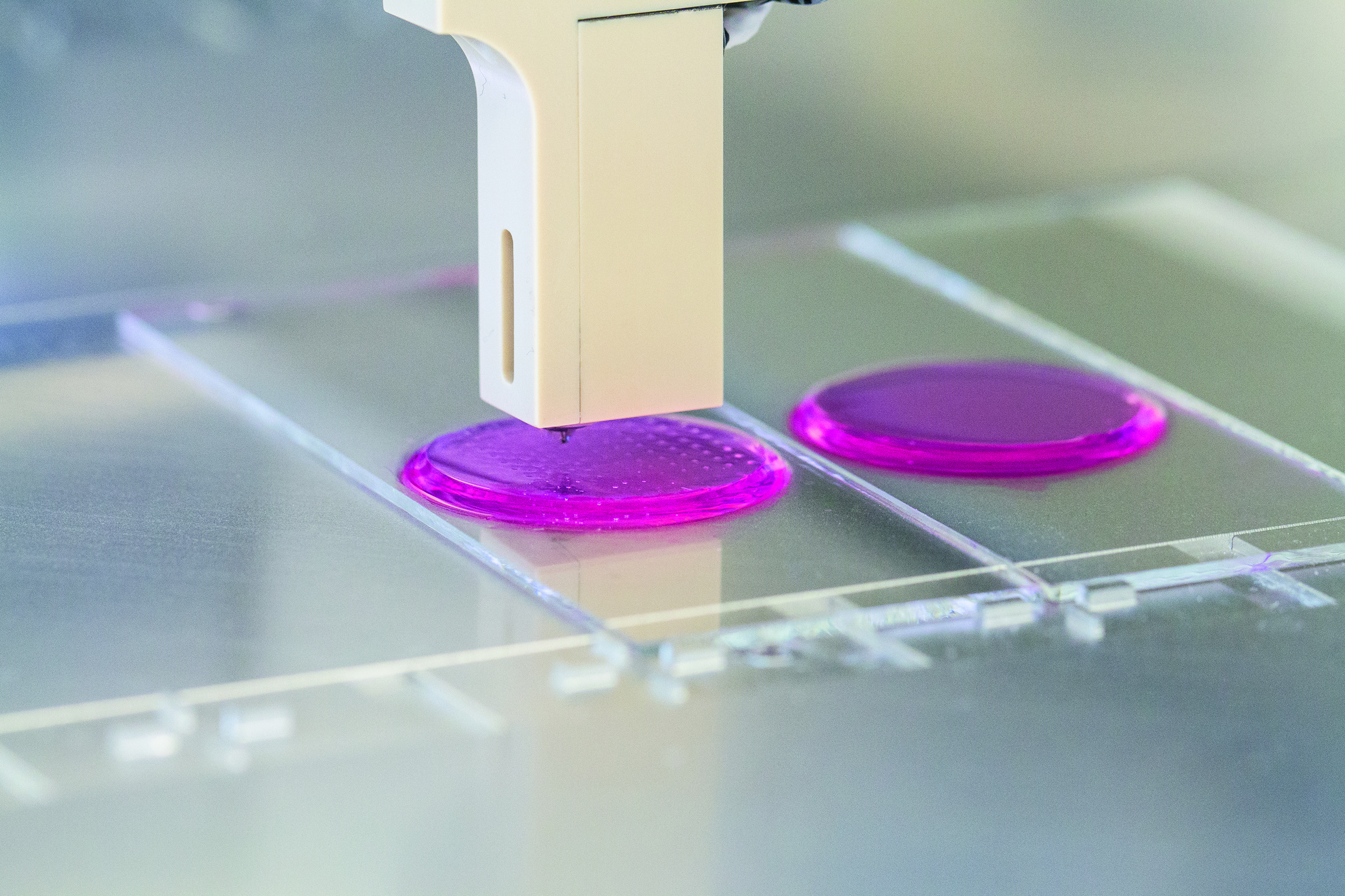

Making quality visible

To improve the reliability and shape accuracy of all additively manufactured products, we develop individual safety systems for your entire product development process:

- Products and processes - reproducible processes & dimensionally accurate products as well as

- Quality management in the production chain - reliability & shape accuracy.

The Fraunhofer Competence Field Additive Manufacturing supports you with its many years of cross-industry knowledge in the integration of quality assurance tools and in the development and optimization of your quality management system.