Shorter process planning phases and consistently high product quality are required to make additive manufacturing processes a real alternative to conventional processes. Digital path planning that automatically takes process fluctuations into account and compensates for them is an important step in this direction.

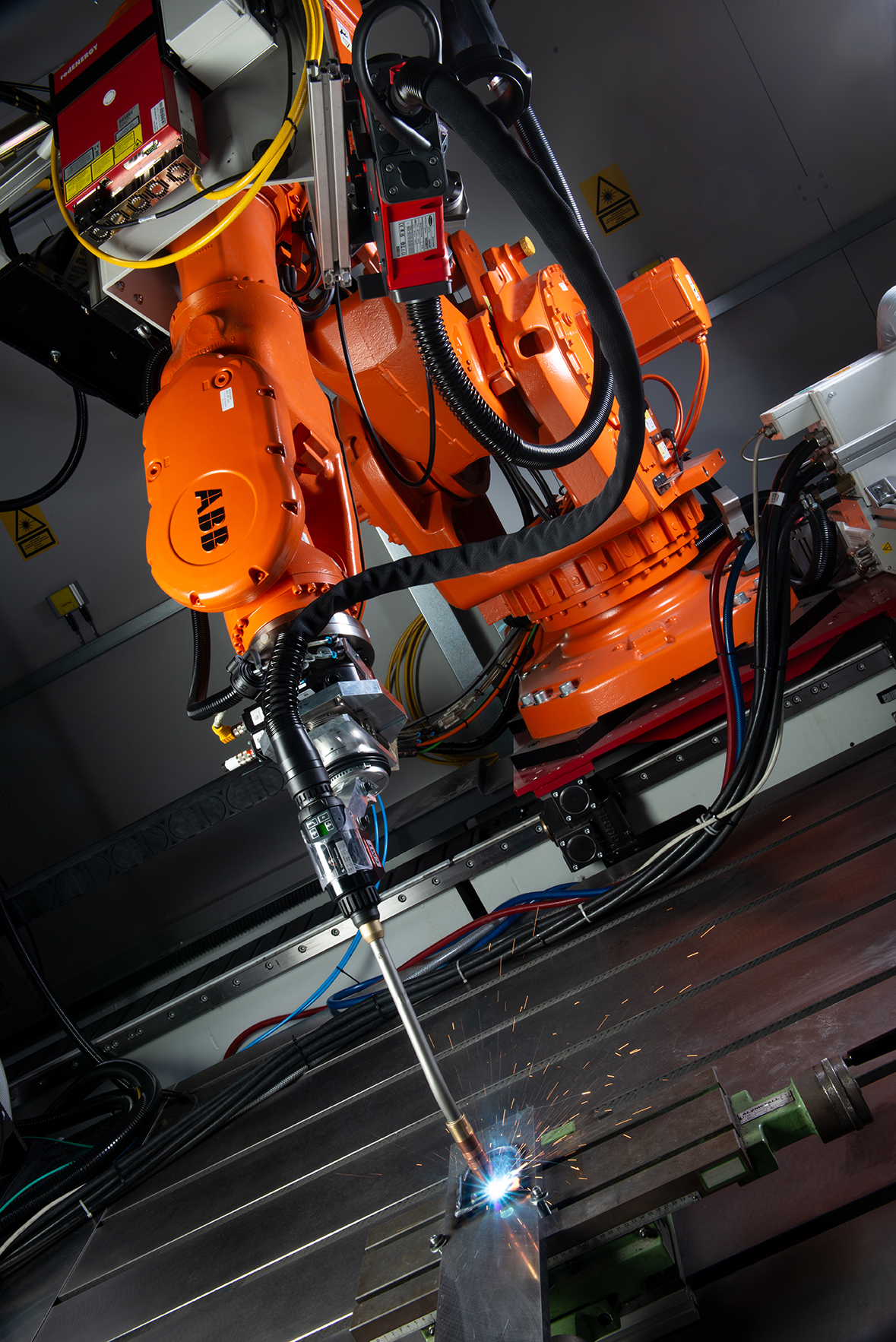

The aim of the research project "KI4ToolPath - Geometry-supported classification of process states for path planning support using the WAAM process" is to achieve fully digital process planning for wire arc additive manufacturing (WAAM). Process errors are recognized and compensated for during path planning with data-based machine learning. Automated process planning significantly improves the reliability and quality of the WAAM process and reduces the throughput time of the manufacturing process by around 20 per cent.

To this end, interfaces between software and hardware components are being developed and implemented for acquiring, forwarding and processing process data. This data will being transferred to an AI platform and will be serving as the basis for training an artificial intelligence system. The developed AI algorithms will be integrated into the web planning software, resulting in digital process planning that also will be taking undesirable process fluctuations into account.

Website:

https://www.ipt.fraunhofer.de/de/projekte/ki4toolpath.html

Contact:

Thomas Derra M.Sc., Telefon +49 241 8904-320, thomas.derra@ipt.fraunhofer.de

Dr. Robin Day, Telefon +49 241 8904-161, robin.day@ipt.fraunhofer.de