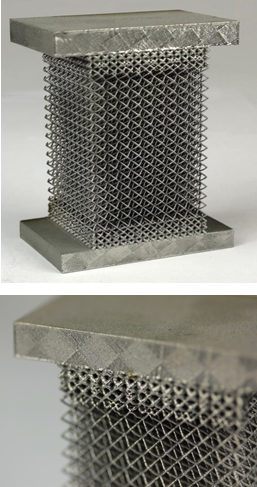

The manufacturing of components containing lattice structures by laser-beam melting combines a weight reduction of the component with time- and cost savings during the production.

The characteristic values required for the prediction of their mechanical behavior by simulation are determined experimentally.

The automation and integration of the mechanical design process into the CAD environment simplifies the use of lattice structures for the user.

In the DFG project »Design and manufacturing of geometrically complex structures using laser beam melting GIHSL (289647464)«, the mechanical design of lattice structures is simplified for the user by automating and integrating the process chain into the CAD environment.

The use of lattice structures is particularly suitable for the manufacturing by means of laser beam melting to reduce the weight of components and for cost saving.

The mechanical design of components with lattice structures is hitherto not adequately possible, they are up to now only used for illustrative purposes.

The characteristic mechanical values of lattice structures required for the design by simulation are determined in tensile tests according to E DIN 50099.

The exposure strategy for production is optimized.

A software tool integrated into the CAD environment simplifies the use of lattice structures on the basis of the determined characteristic values, from the topology selection over the design up to the generation of the data for manufacturing.

The project is carried out in cooperation with TUD / KTC.

Projects:

Design and manufacturing of geometrically complex structures using laser beam melting GIHSL (DFG, 289647464)

Publication:

MS&T 2017, KT 2017 (Abstracts accepted)

Contact:

Fraunhofer IWU, Dipl.-Ing. Hannes Korn, hannes.korn@iwu.fraunhofer.de