Technology and process flow:

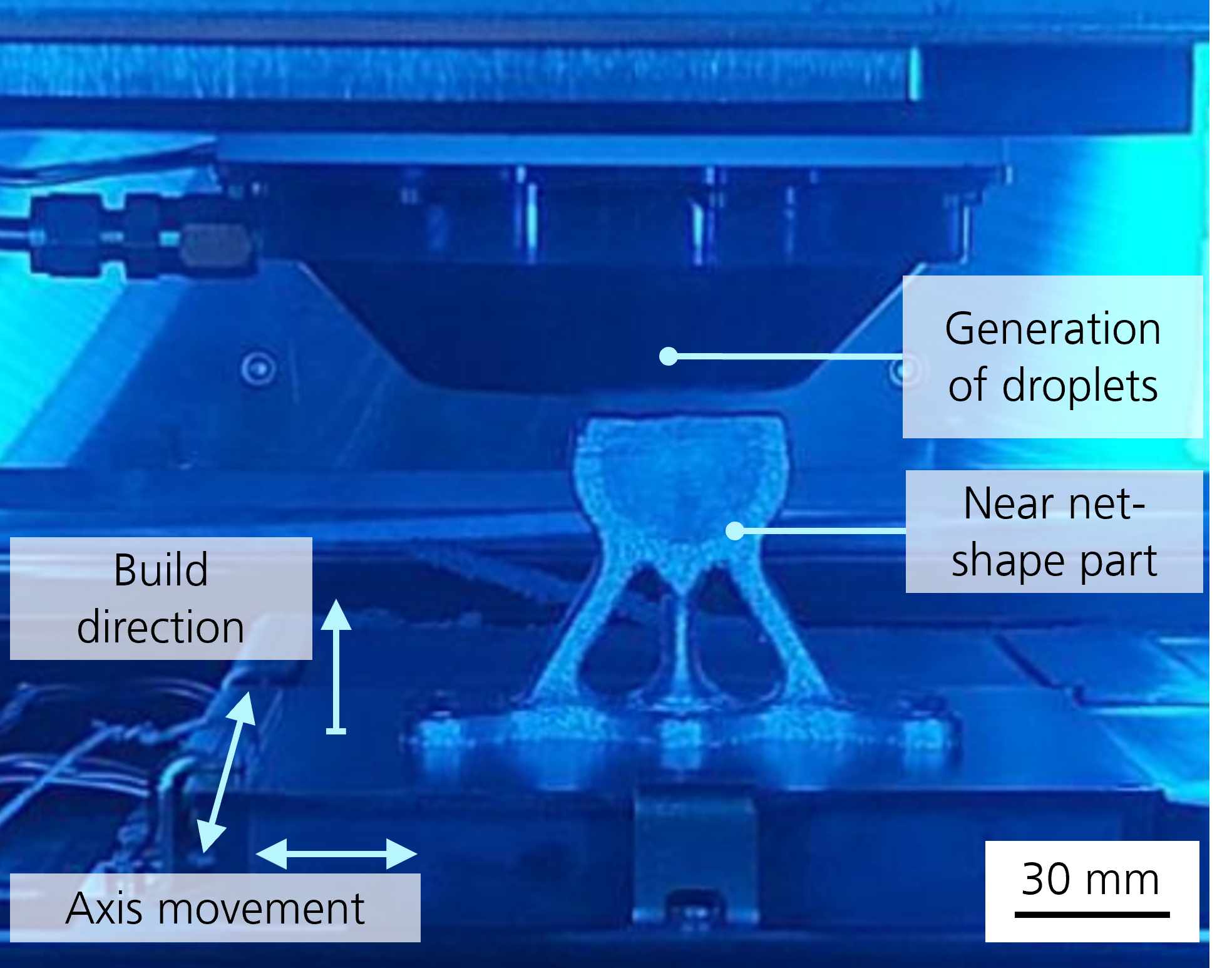

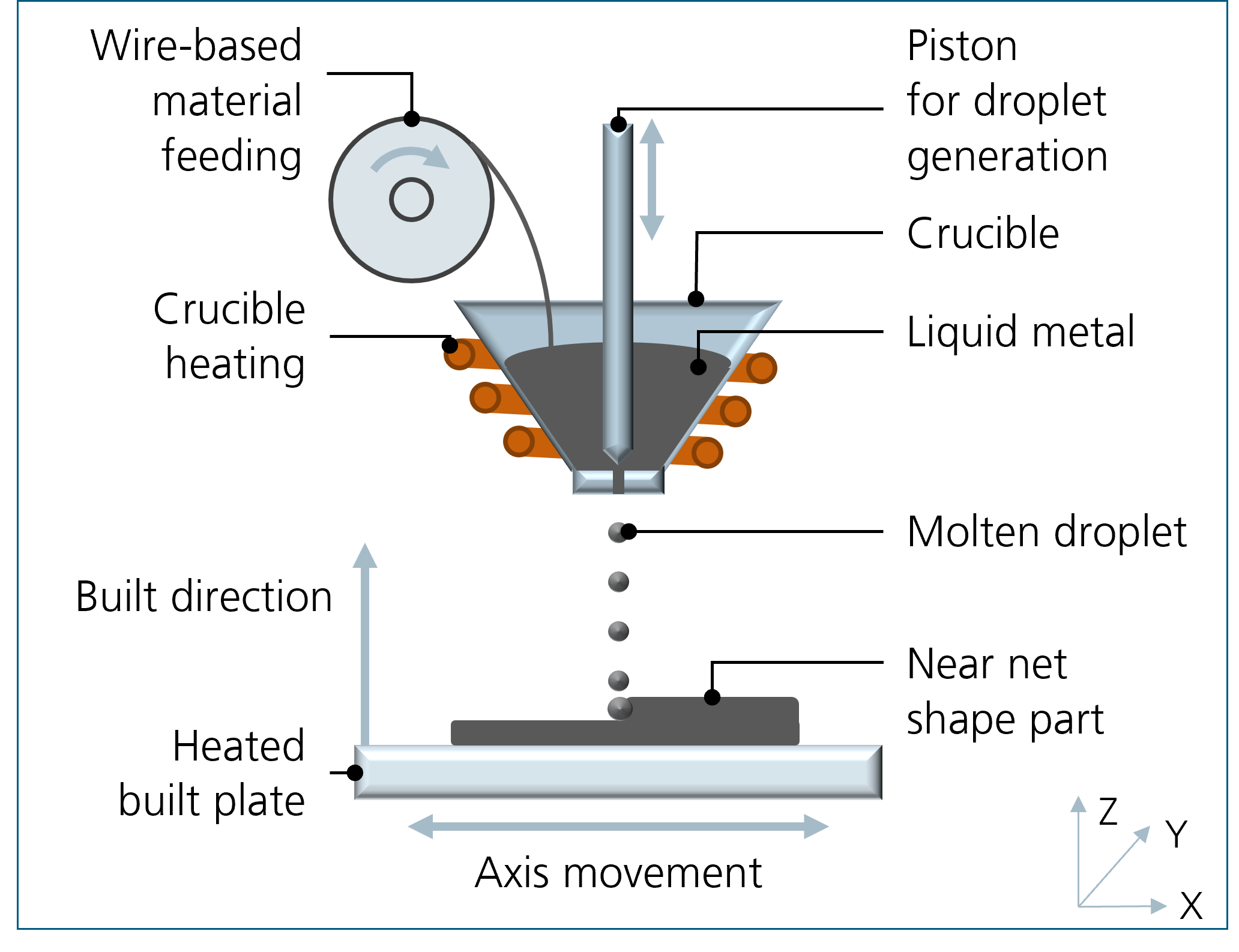

The liquid metal printing process belongs to the group of metal-based additive manufacturing processes (Metal Material Jetting), in which components are built up layer by layer through a repetitive application of the material. Unlike most welding-based processes, liquid metal printing does not require a beam source to fuse the material, as the material is molten and applied drop by drop. Components are built by applying the material in the build direction in conjunction with a high-precision moving cross table (Figure IGCV-ProcessSchemeDesLiquidMetalPrinting, Figure IGCV-PrintingProcessOfAnAluminumHolderAusAlSi12).